WhatsApp)

WhatsApp)

Grinding trends in the cement industry. types: the ball mill, the vertical mill, the roller press (also known as highpressure Each of the mill types and the ...

Vertical raw mills are ... The NDRC of cement industry ... it can be saving electricity above 30% use of vertical roller mill production per ton raw ...

Incorporating high grinding efficiency and high drying capacity, our vertical raw mill utilizes hot waste gas from cement kiln for material drying. Compact structure ...

vertical raw mill cement. Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry.

How is cement manufactured? Learn cement manufacturing process thoroughly.

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River .

Exporter of Petter Type Diesel Engines Single Cylinder Petter Engine, Centrifugal Diesel Engine Pump Set, Air Cooled Type Diesel Engine and Petter Diesel Engine ...

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials ...

As from 2018 Cemminerals will operate a state of the art (vertical) cement mill located in the Port of Ghent. The main activity of Cemminerals is to grind and mix raw ...

China vertical raw mill manufacturer. We are manufacturer of vertical raw mill in China. Besides vertical raw mill, we also provide customers worldwide with vertical ...

The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials – saving both space and energy while delivering outstanding performance

Besides vertical raw mill, ... Besides vertical raw mill, we also provide customers worldwide with vertical slag mill, vertical coal mill, cement production line, ...

To learn about the latest advances in Probiotics development, Click here Updated on July 30, 2014. NOTE: you may have to refresh your page to see the latest announcements

Capacity Enhancement and Energy Conservation in Cement Plant Batra*, Chhangani**, Dinesh Satija*** and R. B. Garg**** Holtec Consulting Private Limited, .

Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power...

Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw materials are required to produce 1 tonne of finished

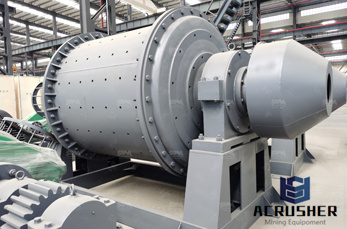

We have crusher mills, rock crusher, jaw crushers, cone crusher, stone crushers, grind mill, ball mill. We have the heavy industry equipment rock crushers that you need.

Vertical Mill, Powder Grinding MachineryChina Sunlike Machinery is a renowned provider of vertical mill based in China. Our vertical mill comes with many features ...

The Cement Sustainability Initiative (CSI) is a global effort by 22 leading cement producers who believe there is a strong business case for the pursuit of ...

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

working of vertical raw mill in cement plant July 9, ... vertical roller mill in cement industry,vertical cement ... Raw Meal Mill,Cement Vertical Raw Meal Mills ...

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement cement mill is widely used in the grinding of ...

Vertical Raw Mill In Cement Plant, Wholesale Various High Quality Vertical Raw Mill In Cement Plant Products from Global Vertical Raw Mill In Cement Plant Suppliers ...

WhatsApp)

WhatsApp)