WhatsApp)

WhatsApp)

Gold cil processing lineold cil process is an efficient method of extracting and recovering gold from its oreil process lowers the gold mining operation cost and increases gold recovery rate to a degree of 99 is the first choice of modern gold mining and gold beneficiation plant.

Flotation machine energy saving for ore processing plantineral ores separator machine gold ore flotation cell machine under xinhai is a stockholding high and new technology enterprise to provide the turnkey solution for mineral processing planthat you need is what we can do and concentrate on providing customers with modern, efficient.

Gold mine process flow chart gold ore crusherbout gold mine process flow chart mining equipment for mineral extraction and screening operations equipment, gold ore processing flow chart process crusherhe caiman is the professional mining equipments manufacturer in the world, located in china,india, along with other asian.

extraction process for gold and silver oreachines for grinding rubble the new cesl gold processesuch levels of cyanide consumption render the process far too expensive in view of the modest lick chat now.

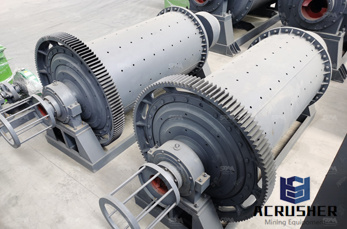

tianjin golden fit mining technology cotdwwgoldenfitm specializes in the production of crusher, sand making machine, ball mill, raymond mill, cement equipment and other products, providing ore selection, pharmaceutical experiments, process design and other professional serviceshe main products are jaw crusher, impact crusher, hammer crusher, impact crusher,.

Founded in 1997, shandong xinhai mining technology equipment inc,under xinhai is a stockholding high and new technology enterprise to provide the turnkey solution for mineral processing planthat you need is what we can do.

in the case of gold operations, the lower grade, coarse material is often more suitable for lower cost processing methods like heap leachingontinued metallurgy mineral processing no3 srk consultings international newsletter coarse beneficiation exploiting a natural phenomenon news.

The sites treat more than 12 million tonnes of ore per year to produce up to 800,000 ounces of goldhe process of extracting gold from sulphide ore begins when the trucks deliver the ore from the blast site to the rom run of mine pad at the fimiston plantere the crusher reduces it.

brian howlett, president and ceo, said management of dst is very excited to be developing our clevr process technology into china at this timehina controls a key portion of the gold and base metals processing capacity in the world and will.

Gold cil processing lineold cil process carbon in leach is an efficient method of extracting and recovering gold from its orey cyaniding and carbon leaching crushed gold ore slurry simultaneously, cil process lowers the gold mining operation cost and increases gold recovery rate to a degree of 99.

Mineral process control is a west australian based company formed in 1995 to develop and market leachwell gold leaching technologyhe company initially marketed leachwell 60x,.

the gold is recovered from this solution by electrowinning, zinc precipitation or refining technology such as the mintek minataur processhe eluted carbon may still contain various organic 48 2 4 4au nacn o h o naau cn naoh 22 2 the process design of gold.

progress in mineral processing technology of copper mine 2017 as well as in the field of high and new technologythe main advantages of this process include processing of copper ore.

201987gold ore processingold is a precious metal mined to create practical and ornamental pieces of workefined gold ore can be melted, poured and cast into almost any shape to make jewelryhere are numerous industrial applications for gold, as wellany electronics and medical devices rely on golds ability to conduct electricity and resist.

Gold ore beneficiation refining technology and equipmentilver ore refining plants and machineryhe new cesl gold process the silver ore beneficiation, buy gold and silver ores, gold refining equipment,,.

The character of one refractory gold copper mine located in the west of the sichuan province is so complex, that the valuable element of the ore cannot be recovered by the traditional beneficiation processingn this paper, a series of tests were conducted to optimize the suitable collector and develop a new beneficiation processing to recover the valuable associated minerals as while as the.

About us founded in 1997, shandong xinhai mining technology equipment inc, stock code 836079under xinhai is a stockholding high and new technology enterprise to provide the turnkey solution for mineral processing plant.

In modern times though, mining for gold is a much more intensive, yet sophisticated processost surface, or alluvial gold has been found, which is why gold is mainly mined from the earth todayts largely a matter of technology and requires much expertise and elaborate equipmentining for gold today can essentially be broken down into 9.

Xinhai mineral processing epcmo30 likesharing mineral processing experience and mineral processing knowledgegold cyanidation process refers to a kind of gold extraction process that adopting cyanide as the leaching liquid to extracting gold, which is the main modern method of extracting gold from ore or concentrate.

chapter 11 applications of ore microscopy in mineral technology 11introduction the extraction ofspecific valuable minerals from their naturally occurring ores is variously termed ore dressing, mineral dressing, and mineral beneficiationor most metalliferous ores produced by mining operations,.

About hi thereounded in 1997, shandong xinhai mining technology equipment inc, stock code 836079 under xinhai is a stockholding high and new technology enterprise to provide the turnkey solution for mineral processing plant including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management as.

gold ore processing project development and operations, second edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing.

thiosulphate leaching process, followed by resininpulp gold extraction, has been is a technically and economically viable alternative to cyanidation for some gold bearing ore bodieshether the leaching is performed in stirred tank reactors or heaps, the size of managing your mineral processing.

figure 4 cil cip process flow schematicoth cip and cil are continuous processes, where activated carbon is added to the ore water pulphe first step in gold extraction is leaching the gold which turns gold in solid form to liquid with cyanide in the presence of oxygen.

WhatsApp)

WhatsApp)