WhatsApp)

WhatsApp)

General description of the reactions in the cement kiln. ... Clinker: reactions in the kiln. The milled and blended raw materials go to a silo and then to the kiln.

Scale and Cement Milling Operations Weatherford International ... Cement Manufacturing Vertical Roller Mills for Finish

classifier equipment operation cement grinding ; Used Industrial Processing Mills For Sale | Machinery and ... Machinery and Equipment buys and sells all types of ...

•Availability of funds 4 CASE STUDY Holtec had carried out a plant operations audit in a dry process cement plant operating at a capacity of about 3,350 tpd clinker.

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

FORGED STEEL BALLS — LARGE DIAMETER Forged Steel Balls are used for gold mining, cement factories, oil processing and large scale industrial applications.

liming Cone Crusher For Sale | Sigma Used Construction . For more details about the liming Cone Crusher or for any general enquiry, fill in the form below and we ...

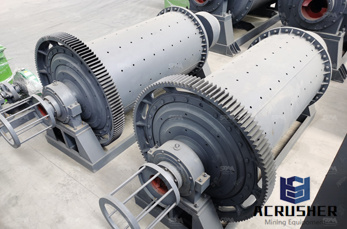

Ball mills account for the majority of all mills in cement plants and therefore the optimization of established ball mills implies high savings potentials. Parameters ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » Several energy efficient options for cement grinding are available today such as vertical ...

A cement mill (or finish mill in ... The cement mills on a cement plant are usually sized for a clinker consumption considerably greater than the output of the plant ...

Ball mills are commonly used in the manufacture of Portland cement and ... It is similar in operation to a SAG mill as ... Tower mill. Tower mills, ...

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden.

Handles turnkey projects and manufactures cement and paper making machinery. Contains company profile, product range and services offered.

Cement is a binding agent and is a key ingredient of the most used manmade material: concrete. The demand for cement is strongly correlated to the rate of economic ...

FLSmidth ball mill for cement grinding. ... In twocompartment cement mills, the first, ... during operation.

Operation of cement ball mill. 82 567 USD. Operation of a cement mill cement ball mill operation ? coal processing system machine for . find the right and the.

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california

Verdana,Bold"Contractors Verdana,Bold"Page of . Verdana,Bold"Construction Supplier Verdana,Bold"Page of . Verdana,Bold"Professional Services

Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding down to nano range. Read more.

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

India is the second largest cement producer in the world. However, it is way behind China, where the capacity is more than five times larger. Cement is a lowvalue ...

4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying

Original manufacturer of the CARDOX CO2 System, SILOWHIP System

WhatsApp)

WhatsApp)