WhatsApp)

WhatsApp)

Notes on chromic iron ore its modes of occurrence, mining, dressing, uses, and value with a register of new south wales localitiesy 1855 joseph edmund carnebstract.

Teachers notes early mining a brief history lead production in the 18th and 19th centuries mining methods bell pits and hushes mining methods levels, stopes, deads and spoil mining methods shafts processing ore the dressing floor processing ore the smelt mill mining landscape where miners lived a life of extremely hard work time for fun and games the end of an era grinton.

Activities related to mining and ore dressing have left a lot of marks in the landscapehey reveal the evidence of structures no longer visible that is the case of dry rivers which cannot explain the large volumes of sediment treated in iron ore dressing workshops.

201982it is suitable for different type of hematite ore, magnetite, gangue mineral and other mineral such as quartz and kaoline production line has advantages of environmental protection, high efficiency and high hematite iron ore precision.

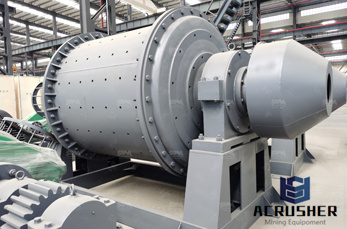

types ore dressing, beneficiation and mining equipment plant which are suitable for coal ore, copper ore, iron ore, gold mine, silver oreur products include drying machine, floatation machine, magnetic separator, concentrating machine, spiral.

iron ore miningshiliabai sardesai is a partnership firm whose core business is iron ore mininghe firm is operating its own mining lease culnasodo kirlapale iron ore mine, over an area of 82 hectares, in village cormonem bandoli of.

Magnetizing roasting mechanism and effective ore dressing process for oolitic hematite oreuthors report of ore dressing of hematite ore with high phosphorus content from process and mechanism of multilevel circulating fluidized magnetizing roasting of refractory iron oxide ores from daye iron mineduhan wuhan university.

The company is engaged in opencast mining operation under mdo contract in iron ore deposit located at kanker district of chhatisgarh with an guaranteed quality65fe ore deliveryt includes mine planning, excavation, drilling, blasting, dump management, screening, crushing and loading the finished goods in to dispatch trucks.

Iron ore mineron oxide mining started in the dunderland valley more than 100 years agontil 1999 iron ore was only mined by open pit methodsoday rana gruber operates the kvannevann underground mine as well as satellite deposits which are mined by openpit methodspen stope mining method has been used in the underground mine until 2012.

america iron ore mining equipmentron is a kind of the earliest was discovered and has the widest range of metal in the worldronas the largest amount metal, the metal consumption of about 95 of total consumptionon ore is mainly used for iron industry and steel industry, smelting iron and steel according tothe different carbon contentth the rapid development of world economy, more.

Iron ore processing depend mainly on the type of rom ore feed and optimum productry screening into lumps and fines is practised for high quality flaky ore and blue dust, because, if wet treatment is used, a substantial part of good quality material is rejected in the form of slimes.

Xinhai mining companyineral processing epcmoinhai devotes to providing turnkey solution for mineral processing plant, namely design and research complete equipment manufacturing and procurementcommissioning and delivery management and operationp to now, xinhai has established multiple overseas offices in the world.

,monograph on iron orebm news letter january, 2019 march, 2019 summary report of the committee in compliance to the directives given by the hon.

201123iron ore processing for the blast furnace courtesy of the national steel pellet company the following describes operations at the national steel pellet company, an iron ore mining and processing facility located on the mesabi iron range of minnesotareating steel from lowgrade iron ore requires a long process of mining, crushing,.

Gain an understanding of the canadian iron ore mining industry, its reserves, historic and forecast data on iron ore production, historic and forecast domestic iron ore consumption, iron ores and concentrates exports, demand drivers, active, exploration and development iron ore projects, the competitive landscape and the countrys fiscal regime.

recovery and dilution usually are interrelated with some methods of stoping a high recovery involves contamination of the ore from the walls or capping, and often clean ore can be obtained only by leaving some ore in the minen openstope mines the greatest loss of ore is that tied up in pillars left for support of the back or hanging wall.

Mining and ore dressingey to the story of how mining developed in britain, these objects relate to a wide range of processes involved in mining and preparing oreshey illustrate the stoically labourintensive nature of the industry, as well as attempts to improve safety and productivity.

Gold cil carbon in leach process is an efficient design of extracting and recovering gold from its orey cyaniding and carbon leaching crushed gold ore slurry simultaneously, cil process lower the gold mining operation cost and increase gold recovery rate to a degree of 99.

Cu pb zn dressing process kaolin mining process titanium mining process chrome ore mining process magnetite separation production line gold cip production line navigation home iron ore mining processntimony mineral processinghrome ore mining processolomite mining processold cil processing lineiew more.

iron ore crusher the common iron ores are magnetite, hematite, limonite, siderite, pyrite, blue iron ore, etcf you are in the field and want to start business about iron ore mining, you need a better iron ore crusher to help you iron ore crusher can process iron ore, copper ore, steel slag, pebbles, quartz, granite, basalt, diabase, etc.

Main iron ore ore dressing technology suppliernode casting shop outotec anode casting shopnsure continuous operation and material flow in your smelter while getting a high return on capital investment with the flexible, modular outotec anode casting systeminimizes rejection rates through high reliability and anode quality uses accurate and reliable selfadjusting operation.

of iron ore, the unaltered ore averaging 44 iron in the short distance of 600 feet of strike length and to a depth of 550 feet below the surface outcrophe only impurity of consequence is titanium which averages 111 tioreliminary ore dressing investigations.

WhatsApp)

WhatsApp)