WhatsApp)

WhatsApp)

an introduction to cement concrete Adapted from the VITA Village Technology Handbook Rural Building by John van W inden and Hand Book of GravityFlow Wa ter Sytems By T Jordan

Dec 17 2012· Introduction of nanotechnology in cement industry has the potential to address some of the challenges such as CO 2 emissions poor crack resistance long curing time low tensile strength high water absorption low ductility and many other mechanical performances

Introduction Of Cement Production Technology Cement production line is composed of a series of equipment to produce cement Device Configuration Jaw crusher rotary kiln cement mill dryer suspension preheater calciner dust removal equipment and other equipment

Summary of production process Cement is typically made from limestone and clay or shale These raw materials are extracted from the quarry crushed to a very fine powder and then blended in

1 basic introduction to PLC PLC control technology in the application of cement mixing cement mixture system as a main equipment in the cement manufacturing if the role of the clinker and slag powder by transmission equipment distribution into the bin according to the water mud after production formula is to be performed for each mixing

Oil and natural gas are the dominant fuels used in cement production Qatar''s cement industry statistics 2006–2011 are plotted in Fig 11 for the indexed cost of electricity and crude oil used in production against the indexed cost of cement Qatar Statistics Authority 2013 NBK Capital 2010 Qatar as a major producer of natural gas has stable fuel costs for electricity generation

The Introduction of Cement and Concrete Technology in Vietnam It is widely recognized that cement and concrete technology is developing and concrete production amount and batching plant increases year after year in

Extraction and processing Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones slates and some shales with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by excavators

The World War I gave the first initial thrust to the cement industry in India and the industry started growing at a fast rate in terms of production manufacturing units and installed capacity This stage was referred to as the Nascent Stage of Indian Cement Company

The seasonal nature of the industry can result in large swings in cement and clinker unfinished raw material inventories at cement plants over the course of a year Cement producers will typically build up inventories during the winter and ship them during the summer

Cement Manufacturing Transparency Reporting As an early industry sector responder to evolving green building requirements PCA and its members were among contributors to the creation of 2014 Product Category Rules PCR on North American cements published by ASTM Product Category Rules For Preparing an Environmental Product Declaration for

Mar 14 2015· INTRODUCTIO N Cement was first invented by Egyptians The Greeks and the Babylonians brought about some changes in the original cement composition Later the Romans produced cement from Pozzolana an ash found in all of the volcanic areas of Italy by mixing the ash with lime The manufacturing of cement was started in England around 1825

CCS is a new technology not yet proven at the industrial scale in cement production but potentially promising CO 2 is captured as it is emitted compressed to a liquid then transported in pipelines to be permanently stored deep underground Cement is a global

Concrete Introduction Concrete is a composite with properties that change with time During service the quality of concrete provided by initial curing can be improved by subsequent wetting as in the cases of foundations or water retaining structures However concrete can also deteriorate with time due to physical and chemical attacks

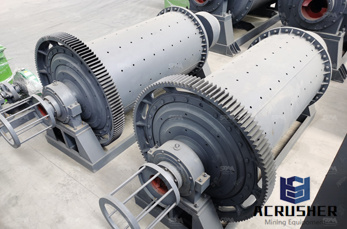

1 basic introduction to PLC PLC control technology in the application of cement mixing cement mixture system as a main equipment in the cement manufacturing if the role of the clinker and slag powder by transmission equipment distribution into the bin according to the water mud after production formula is to be performed for each mixing weighing process and then through the use of ball mill to stir and then

industry can result in large swings in cement and clinker unfinished raw material inventories at cement plants over the course of a year Cement producers will typically build up

Aug 30 2012· Cement Manufacturing Process Phases Production of cement completes after passing of raw materials from the following six phases These are Raw material extraction Quarry Grinding Proportioning and Blending Preheater Phase Kiln Phase Cooling and Final Grinding

Cement producers have faced a significant rise in energy costs with the introduction of dryprocess kilns with a record average consumption of 100200 kWh per ton of cement according to the 2009 Cement Plant Operations Handbook This complex challenge coupled with rising fuel and energy costs

Aug 19 2011· Introduction A cement is any substance which binds together other materials by a combination of chemical processes known collectively as setting 1 Cements are dry powders and should not be confused with concretes or mortars but they are an important constituent of both of these materials in which they act as the glue that gives strength to structures

Aug 30 2012· Cement is the basic ingredient of construction and the most widely used construction material It is a very critical ingredient because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix

structures Cement is an extremel y important construction material Cements used in construction can be characterized as being either hydraulic or nonhydraulic The first step in the manufacture

Cement in general adhesive substances of all kinds but in a narrower sense the binding materials used in building and civil engineering construction Cements of this kind are finely ground powders that when mixed with water set to a hard mass

WhatsApp)

WhatsApp)