WhatsApp)

WhatsApp)

Cement Lincoln, Nebraska, USA Diagram of a Modern Cement Plant *Click on object for more information Cement Production 3DLevelScanner Prehomogenizing Hall Application: The raw materials ...

Storage and Homogenisation The crushed limestone, shale and marl are conveyed to the mixing bed where the gravel is mixed to a homogeneous material. The chemical composition of the material is carefully monitored to ensure ...

Home » Projects » omogenisation in cement process omogenisation in cement process Main Projects: Magmatism dominated intracontinental rifting in ., Patent WOA2 Production of mixedmetal .,, ...

Dry Process Cement Production Line | PENGFEI Group pre homogenization process in cement industry,Dry Process Cement Production Line New Type Dry Process Cement Production Line How does the dry process cement ...

Cemnet has wide application as a vital construction material. We are a professional cement storage silo manufacturer, and our customer offers us this useful cement manufacturing process. ... Cement is one of the most common and ...

Our dry process cement plant is fitted with our PC1609 hammer crusher for auxiliary material crushing. Raw mix homogenization, and feeding raw mix into preheater ...

With rich experience in mineral processing, we can offer advanced and reasonable complete solutions for pre homogenization process in cement industry. The technics of Cement production process . Henan Heavy Industry ...

Homogenization Strategy in the Cement Industry Cement clinkering process quality assurance demands specific chemistry and consistency of the kiln feed for a stable operation. This brings to focus the importance of the Blending ...

pre homogenization process in cement industry Prehomogenization adopts the ... In cement production process, cement crusher is very important ... Posts Related to raw material homogenization in cement. crushing and pre ...

Homogenization (chemistry) Wikipedia, the free . Homogenization or homogenisation is any of several processes used to make a mixture of two mutually non ... pre homogenization process in cement industry pre homogenization ...

During cement manufacturing process of dry process of cement manufacturing, to homogenize the constituent of fed raw materials is the premise of stable clinker sintering. ... The raw material homogenization system is the last ...

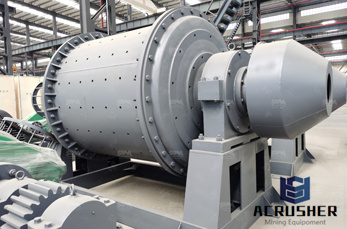

1. Crushing and prehomogenization (1) Crushing In the production process of cement, we have to crush most of the raw materials, such as limestones, clay, iron minerals and coals. The limestone has the largest proportion among ...

Homogenisation Silos Al Bijjar Trading (FZC). Al Bijjar Trading (FZC) is the leading supplier to the Cement Industry worldwide and specially in th ... Cempak Engineering Consultants We are consultants to the cement industries ...

Sampling in the cement industry 6 Sampling takes place throughout the cement plant for checking chemical processes, process optimisation and checking silo homogenisation as well as for documentation of product quality at ...

Industrial Waste as Alternative Fuel in Cement Industry: Its Impact on Environment controlling the above factorsASPEN PLUS could also be used to calculate the heat balance of the entire process using established thermodynamics ...

In the new type dry process cement production, stabilizing the ingredients of the raw materials is the precondition of clinker calcining pyrology system. The homogenization system is a final check for the process. 4 Decomposition ...

Grinding and homogenization Al badia cement The grinding process takes place in a raw mill to reduce the particle size of the components to a typical value of ... How Cement is Made HeidelbergCement Group to cement.

Crushing During cement manufacturing process, the majority of raw materials, including limestone, clay, iron ore, coal, etc. will be crushed. Specifically, due to larger granularity and higher hardness, the crushing of limestone that is ...

Stacker and reclaimer systems for cement plants SBM systems for cement plants ... cement industry, matching kiln through puts of up to .... cases where homogenisation is not nec essary. The pile is ... process continues in the ...

This paper deals, in the framework of homogenization theory, with a problem arising in civil engineering. A periodic masonry structure is considered where the constitutive materials are bricks and mortar. Global mechanical properties ...

Grinding and homogenization The grinding process takes place in a raw mill to reduce the particle size of the components to a typical value of 1015 % residue on a 90 um sieve. The output of the grinding process – called ''raw meal ...

2 Futureoriented raw material preparation solutions made by Polysius: Innovative – Individual – Ideal. The manufacturing of cement begins with the extraction and preparation of raw material – a process covering the stages from raw

View a 3D animated video of the cement production process to learn how cement is made by CEMEX ... 6. Raw material mill This takes places in vertical steel mill, which grinds the material through the pressure exerted by three ...

2011/12/20· The old calculation method of a cement mixture is based on the principa Skip to main content SpringerLink Search Home Contact Us Log in Arabian Journal for Science and Engineering ...

WhatsApp)

WhatsApp)