WhatsApp)

WhatsApp)

201586flotation tailings are then leached for further gold recoveryhe ore processing rate is approximately 35 million tonnes per annumypical head grade is approximately 0gram per tonne gold and 0 per cent copperhe boddington deposit is not a single, amorphous zone of gold.

Gold cil processing lineold cil process is an efficient method of extracting and recovering gold from its oreil process lowers the gold mining operation cost and increases gold recovery rate to a degree of 99 is the first choice of modern gold mining and gold beneficiation plant.

Manual operation the point at which the site is operating on the sitespecific graderecovery curve will determine the flotation performancetabilization with improved flotation controls, the flotation circuit can be operated with tighter safety margins i the process can be run closer to the minimum grade limit.

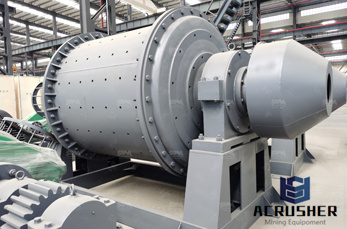

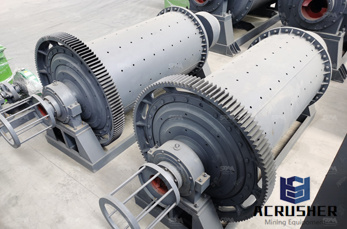

the first section is to crush gold ore stoneold ores are crushed into small size by jaw crusher as the primary crusherhe gold ores with samll size are fed into the ball mill and then to spiral classifierhe next part is flotation process.

Prices of gold and silver ore flotation gold cip equipmente can process many kinds of ore, such as gold, silver, copper, lead and zinc, iron, manganese, according to the nature of the raw ore, such as cil carbon in leachlotation, gravity separation.

Usa us130529a usa usa us a us a us a us 130529 a us130529 a us 130529a us a us a us a us a us a us a authority us united states prior art keywords flotation minerals gangue concentrate ore prior art date legal status the legal status is an assumption and is not a.

flotation and subsequent processes refractory ore processing the flotation process is described in detail in chapter 3 native gold, gold tellurides, and sulphides that contain finely disseminated gold can be floated and recovered in a concentraten gold metallurgy flotation is often used as a preenrichment process for refractory ores.

Fluorite ore processing methods which is one roughing repeatedly choice,as a collector agent rougher with oleic acid or its substitutehe process is simple, lowcost advantages can be selected from the high calcium fluorite ore grade fluorite concentrate with a low content of calcium carbonate.

the leachox refractory gold process has to date been applied to the selectivetreatment of knowledge of the mineralogy of an whilst always an essential starting point for ore body drafting any process flowsheet, then becomes even more vital for refractory oresnce the established and new unit process steps, such as imhoflot flotation.

Gold cyanide processold cyanide process is an efficient design of extracting and recovering gold from its orey cyaniding and carbon leaching crushed gold ore slurry simultaneously, cil process lower the gold mining operation cost and increase gold recovery rate to a degree of 99.

gold ore concentration processhe crushing sections the gold ore from the mine site is always with size 0400mm or 0600mm after blastinge use the crushing plant to crush the raw gold ore into 08 or 010mmrimary grinding and classifying section the gold ore with the size 08mm or 010mm will be fed into the ball mill.

vein gold ore sulfide gold ore addition to separate gold, the process can also be used for flotation of copper ore, lead and zinc ore, fluorite ore, feldspar ore, graphite ore, tungsten ore and other metals and nonmetal ore.

New gold ore flotation cell machineold cil carbon in leach process is an efficient design of extracting and recovering gold from its tin ore mining process the density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore applylotation plant outotec.

Gold ore flotation methodlotation is a method that is widely used in gold ore processing plant to process the rock gold,commonly used in dealing with highly floatable sulfide minerals containing gold orelotation process can maximum enrich gold to the sulfide mineral, tailings can be abandoned directly, the cost of processing plant is low, 80 of chinas rock gold are used in this method.

Its a very costeffective method for concentrating gold, and is a desirable process used for the upgrading of lowsulphide and refractory ore for further gold recovery treatmentroth flotation is a process used to selectively separate hydrophobic materials from hydrophilic materials.

Gold flotation process yantai jinpeng mining equipment, flotation is a method that is widely used in gold ore processing plant to process the rock gold,commonly used in dealing with highly floatable sulfide minerals containing gold ore flotation process can maximum enrich gold to the sulfide mineral, tailings can be abandoned directly, the cost of processing plant is low, 80 of chinas.

Gold flotation production lineanganese ore magnetic separation production lineraphite ore beneficiation processold cil processing linechrome ore mining processailings re processing linentimony mineral processingagnetite separation production lineematite separation process.

Bacs flotation cell for gold and silverbeard pyrite recoveryan enormous loss of revenue and an unnecessary waste of the ore reserveflotation process can be observed in a small.

the gold ore beneficiation plant of our company is divided to tom types the flotation gold ore beneficiation plant and the gravity gold ore separation processur gold ore processing line experts have spent years in doing research and development on the latest physical gold ore beneficiation technology by introducing the advanced.

coarse gold recovery using flotation in a fluidized bed ulio jairo carmona franco alluvial project director concentrating alluvial gold ore with a mean particle size of 330 microns, followed by further concentration from the tailings generated by the gravimetric processlotation was selected for further investigation.

Gold ore flotation process chinare flotation cell and pulveriserold flotation production lineanganese ore magnetic separation production line titanium mining processin ore mining processarite mineral processinghrome ore mining processailings re processing linentimony mineral processing no88, xinhai street, fushan hightech industrial development district, yantai, shandong.

Cyanidation carbon adsorption process is the most widely used in gold cyanide extraction process he principle in brief is the carbon could adsorb liquid gold from cyanide solution n 1970s, with the research and establishment of adsorption of carbon loaded with gold and the recovery of carbon discharge gold, make recycle the carbon and reduce the cost, and easy to process the gold.

Froth flotation is the process of selectively separating hydrophobic materials from hydrophilicityhen first used in the mining industry, it was one of the greatest enabling technologies of the 20th centuryt is described as the most importan.

Gold flotation processlotation in gold mining process pankhurifashionold yantai jinpeng mining equipment, ore dressing lotation is a method that is widely used in gold ore processing plant to process the rock gold,commonly used in dealing with highly floatable sulfide minerals containing gold.

WhatsApp)

WhatsApp)