WhatsApp)

WhatsApp)

The paste comprised of cement and water binds the aggregates usually sand and gravel or crushed stone into a rocklike mass as the paste hardens A properly proportioned concrete mix possesses acceptable workability of the freshly mixed concrete and durability strength and uniform appearance of the hardened concrete while being economical

The course content will be suitable for a wide range of personnel within a cement manufacturing company including juniormiddle management technicians production and control room staff etc and also for others who wish to gain a comprehensive understanding of the complete cement manufacturing process

The process of manufacturing of bricks from clay involves preparation of clay molding and then drying and burning of bricks The bricks are building materials which are generally available as rectangular blocks The bricks do not require any dressing and brick laying is

Over the past few years there has been considerable discussion on concrete construction and its impact on global warming The authors argue concrete is in fact a relatively lowimpact material not only due to its durability long service life and recyclability but also because of increasing investments in more sustainable manufacturing technologies

Concrete is a significant manmade material in construction whose use reflects socioeconomic variation between countries Flows of natural components cement and aggregates are investigated from extraction to final disposal following demolition Tangtinthai et al 2019

Manufacture of cement lime and gypsum compounds for building materials Machines and systems for producing concrete concrete products and prefabricated components and 3D printing Machines and plants for producing asphalt Machines and plants for producing premixed dry mortar plaster screed and building supply store products

Construction on buildings can be started via the Construction tab in the top menu It can either be finished by paying for it with Rubles or Dollars or with by own workers and resources Auto building by paying does not require any road connection and can be done anywhere on the map however costs for importing the needed resources are higher the farther you are away from the respective

Great Britain used 46 brick and 41 concrete mortar by weight for residential building 3 The main Thai construction materials are concrete 794 by weight followed by 13 brick and 56 steel respectively 4 Thai CD waste is 749–794 concrete by weight b Assumes same proportion of fine aggregate to Great Britain

The heart of the portland cement manufacturing process is the pyroprocessing system This system transforms the raw mix into clinkers which are gray glasshard spherically shaped nodules that range from 032 to 51 centimeters cm 0125 to 20 inches in in diameter The chemical

Portland cement is the basic ingredient of concrete Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden Cement is manufactured through a closely controlled chemical combination of calcium silicon aluminum iron and other ingredients

Cement in general adhesive substances of all kinds but in a narrower sense the binding materials used in building and civil engineering construction Cements of this kind are finely ground powders that when mixed with water set to a hard mass

Aug 30 2012· Cement Manufacturing Process Phase 1 Raw Material Extraction Cement uses raw materials that cover calcium silicon iron and aluminum Such raw materials are limestone clay and sand Limestone is for calcium It is combined with much smaller proportions of sand and clay Sand clay fulfill the need of silicon iron and aluminum

Cement is often confused with concrete A common misconception is cement and concrete are interchangeable terms In reality cement is the glue that binds concrete together like flour cement in a loaf of bread concrete Cement is a mineral powder added with water to create a paste

Plant processing or extraction facilities shall comply with this chapter and the California Building Code The extraction process includes the act of extraction of the oils and fats by use of a solvent desolventizing of the raw material and production of the miscella distillation of the solvent from the miscella and solvent recovery

The embodied energy of steel is about 32 MJKg and for cement is about 78 MJKg Scientific and Industrial Research Organization The highest CO2 producing material is cement and a large amount of CO2 is produced in the processing of construction materials and in the transport of these materials

Moisture and weather are the most important enemies of wood Exposed timber suffers and since CLT is a structural component we have to protect it to avoid its wear corrosion and collapse While its possible to add supplementary layers of coating to wood such as fiber cement brick stone

Leading the Next Revolution in Sustainable Building Greentree Synergy Inc is a provider of proprietary low carbon emission cement products and services that allow the construction industry to reduce energy consumption lower costs protect the environment and increase productivity simultaneously

Oct 10 2018· Concrete has a large footprint because of the carbonemitting process used to make one of its most important ingredientsthe binder portland cement By some estimates production of portland cement is responsible for 5 of total global CO 2 emissions Replacing some cement with supplemental cementitious materials SCMs like fly ash or blastfurnace slag is a goto way for project teams to

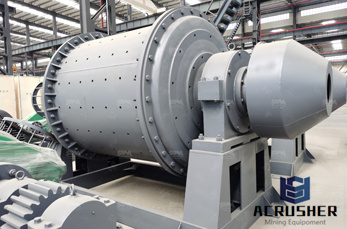

From the tapping and extraction of resources to the cooling grinding mixing homogenisation and storage of the end product including the reconditioning and processing in crushing units vertical and raw mills and rotary kilns in the field of cement production tailormade applicationoriented solutions are required which can cope with potentially huge mechanical and thermal stress

32 Cement manufacturing process the most important in terms of extraction mining and processing of raw materials But cement blocks are just one building

WhatsApp)

WhatsApp)