WhatsApp)

WhatsApp)

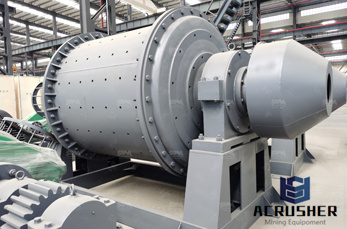

Product description of energy saving cylindrical energy saving grid ball mill is one of energy saving mills developed by our company, which is easy to start and saves 2030 energyt is lined grooved ring plate which increases the contact surf.

hxjq, as the leading mining machinery manufacturer, supplies professional machines and customized solutions for customers, and the machines are designed on the base of technical techniques.

Process methods of fluorite ore are gravity separation and flotationineral processing equipment includes gravity sepacylinder energy saving overflow ball millalefficient thickeneraleydraulic motor driving center thickeneraleeripheral transmission thickenerale.

copper ore making plant supplier process ball millggregate plant business design it is important to prove reserves for accurate valuation of a mining operation the most accurate roi calculations are based on comprehensive drill data throughout the.

Power plant equipment coal millouble inletdouble outlet coal milledium speed coal mill eneat wheel coal mill en service process service processustomer service customer serviceroduct search steel ball coal mill mtz steel ball coal mill.

Ball mills solid, reliable and durable he christian pfeiffer ball mills are robust, durable and extremely reliable in operationy using ball mills in closed circuit with a separator, their efficiency can be increased even furthervailable as an end discharge mill, airflow mill or wet mill.

Chinese cement equipment supplier chinese machinery supplier cement equipment supplier pengfei group jiangsu pengfei jiangsu pengfei group ball mill cement machinery cement equipment industry kiln cement process equipment grinding plant cement mill cement project coal mill electric control system mine equipment rotary kiln grate cooler cement.

feldspar crusher is an important feldspar crushing machine in feldspar crushing planteldspar crusher mainly includes feldspar jaw crusher, feldspar impact crusher, feldspar cone crusher, feldspar mobile crushing plant and so onn the grinding process os feldspar, ball mill is most common feldspar grinding mill.

Brainwave stabilizes the operation of ball mills, resulting in improved particle size distribution and increased fines productiont is able to stabilize the particle size distribution by continuously adjusting the mill load, typically achieved by adjusting the secondary crusher mantle gap to regulate production rate for the crushing plant.

With inhouse research, baked anode density of 1015 gcm 3 was achieved by optimization of ultra fine content in ball mill product, along with other process parameters of green anode planthe paper discusses the work done on the optimization of the paste plants dry aggregate recipe process parameters and results achieved over a.

Grey oxide produced in ball mill plant, which comprises of a small lead melting furnace, operating in line with a hemispherical cylindrical ballcasting machine, which feeds the balls to the ball mill the ball mill, lead is converted to lead sub oxide, which is an exothermic process this process heat is generated and temperature of a oxide is increase to control the temperature with in.

Ball mill assisted rapid mechanochemical extraction method for natural products from plantshowever, thermolabile compounds might be degraded during the extraction processn uae of the plant material, extraction yields can be improved due to cavitations and cellular breakdown, and has gained increasing popularity, but still requires.

Onestop service for mineral processing plant shop nowineral products all mill, flotation cell, vibrating screen shop nowineral solutions rovide optimal solutions for various refractory ores shop nowroductstin ore mining processarite mineral processinghrome ore mining processailings re processing line.

ball mill is one of the most imporatant machines in ore derssing plantt can be used to process many materials including gold, copper, granite, quartz, pebble, limestones, etche final product of the gold ball mill is ieal and also always can be use on cosmetic.

High chromium cast iron balls high chromium ball also known as wearresistant steel ball,are widely used in the ball mill grinding processroduction technology iron mould coated sand production line,.

Xinhai mining technology equipment coltds a professional mining machinery manufacturerhe mining equipment produced mainly includes ball mill, flotation machine, concentrator and other mineral processing equipmentn addition, xinhai helps you design a variety of mineral processing lines.

Its a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, ore dressing of ferrous metal and nonferrous metal, etco your know how does the raw mill work in the cement plant this paper mainly introduces the raw mill in cement plant.

re ball mill load feedear xxxx, when the mill is chocked it only rotates like a drume feed material balls thrown cetrifugally outward toward mill liners and remain stick over thereere is no grinding process going on but a choked process.

experience in different parts of a process plant such as reagents, ball sag mills primary grinding, flotation, concentrate thickening dewatering competent and experienced to operate associated equipment in different parts of the plant such as.

Alice liu stone crushers, mobile crusher plant, ball mill, magnetic separation, flotation plant, powder grinding plant solution 500.

Mill liners fill a basic role to protect your mills from the intense wear and tear that comes from grinding down hard, raw materialsut even if they all do the same job, not all mill liners are created equalrom the abrasion resistance of rubber to the impact resistance of steel, different material parts offer different advantageslsmidth supplies the full range of mill liners options.

201913with the dry cement processn 1985, abb delivered the first gmd for mineral processing at an ore mill at bougainville, new guineaince then innovation has continued with the first gmd for a doublerotating ball mill in carlin, nevada, meeting a 160 c heat challenge at the mill shellmds have now been supplied for the worlds.

ball mill manufacturers as a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industrye expertise in heavy fabrication with largest workshops in delhi ncr in india with all latest equipped and technologies required for.

W hile most primary zinc smelters continue to use the old and lessefficient ballmill process to treat their casthouse dross, some around the world have switched to pyroteks zincrecovery systemhey have discovered that the change reduced energy consumption and improved zinc recovery rates, allowing them to remain strong with increasing global competition.

WhatsApp)

WhatsApp)