WhatsApp)

WhatsApp)

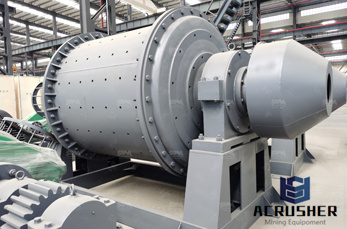

Wet process ball mill Feeding size:≤25mm Motor Power: Wet process ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore ...

Optimization of mill performance by using online ball and pulp measurements Soon after a stop, a mill is a dangerous place to enter for the personnel tasked with taking measurements or samples. Crash stops are difficult to ...

dry feeding to ball mill ball mill feeding process Ball mill,Ball mills,Ball mill machines Machinery. Ball mill is the key equipment for grinding after the crushing process, ... » Learn More Ball Mill Manufacturer,Ball Mill,Raymond Mill ...

Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing . In case of continuously operated ball mill, the material to be ground is fed from . Ball mills are used extensively in the ...

Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the ...

A ball mill is widely used in cement, silicate, new construction material, refractory material, chemical fertilizer, ferrous metal and nonferrous metal as well as ceramics. It is widely applied to dry or wet grinding for ores and grindable ...

Ball Mill is made up of feeding part, discharging part, gyre part, transmission part, (decelerator, small transmission gear, generator, electrical control) and so on. Application : Cement Plant, Clinker Grinding Unit, Steel Mill, Quicklime ...

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal ...

Dry process ball mill Cylinder speed:1838r/min Weight: Feeding size:≤25mm Dry process ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material ...

Ball mill, a type of grinding mill, is a cylindershaped device used to grind materials like ores, chemicals, ceramic raw materials and paints. The ball mills are the key milling equipment after material has been crushed. It is divided into ...

Ball Mill Ball mill as most common grinding equipment, play an important role in crushing and mining industry. It can be helpful in the process of metallic powders, gypsum wallboard additives, bronze powders or minerals, carbon or ...

Versatile system based on standard modules 2 The FLSmidth ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. The mill may operate in either open or closed circuit and with or ...

Ball Mill Manufacturers, Ball Mill Suppliers Global Sources Wide range of Ball Mill manufacturers from Global Sources High quality Ball Mill supplied by Ball Mill suppliers. Ball mill Wikipedia, the free encyclopedia A ball mill is a ...

The ball mill feed in the form Detailed Henan Zhengzhou ... ball mill feed device for feeding of ball mill is a complete system, which has great influence on the ball mill output. The traditional feed form generally has three ... » Learn ...

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Types of ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ...

Ball Mill Ball mills are used for single stage fine grinding, regrinding processes. After the crushing process a ball mill is one of the most important equipment used for secondary grinding. Size reduction is carried out through Impact of ...

Hammer mills Unit Operations in Food Processing RL Earle The mechanism of fracture is not fully understood, but in the process, the material . In a jaw crusher, the material is fed in between two heavy jaws, one fixed and the and ...

Ball Mill Feeding Granularity: ≤20≤25mm Applicable Range: Cement, silicate product, new building material, refractory material, fertilizer, black and nonferrous metal ore dressing and glass ceramics production industry etc. copper ...

And the feeding particle size of mini jaw crusher is about 125mm750mm. ... uring the running process of ball mill, rotary rate is. ... With the highest spindle motor speed limited to differentiate, there. Quick and Easy Black ...

Pendulum feeder is widely used in the material feeding process ... to ball mill or belt conveyor. ... to ball mill or belt conveyor. Pendulum feeder has ... >> Get Price Ball Mills CONVEYOR BELT Stoock | Crusher Mills, Cone ...

Ball Mill The ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal ...

Structure of Ball Milling: The ball mill is composed of feeding part, the discharging part, turning part, transmission part (reducer, small driving gear, motor, electronic control), the main part of. The hollow shaft using steel, lined with ...

Metallurgical Content1 SCOOP FEEDERS2 SPOUT FEEDERS3 DRUM FEEDERS4 COMBINATION FEEDERS Each application dictates the selection of proper feeding arrangement. This depends upon whether the grinding will be ...

WhatsApp)

WhatsApp)